Shorter lead times. Your deadlines met.

Make the most reasonable plan according to your needs

More precise machining, more reliable performance.

A. Energy-saving measures

1, plastic magnetic pump: advanced hydraulic model, pump shell rolling process.

2, metal magnetic pump: advanced hydraulic model, Hastelloy isolation sleeve and impeller runner polishing.

B.Energy-saving effect

Plastic magnetic pump

1. Advanced hydraulic model improves efficiency by 4-8%;

2, the pump shell rotoplastic than lining plastic increased by 9-12%.

Metal magnetic pump

1. Advanced hydraulic model improves efficiency by 4-8%;

2. Hastelloy improves efficiency by 14-18% compared with stainless steel isolation sleeve;

3. The impeller runner polishing improves the efficiency by 4-8% compared with unpolished.

C.Energy-saving value

1, plastic magnetic pump: use 3-4 years can rely on electricity to recover equipment investment;

2, metal magnetic pump: use 1-2 years can rely on electricity to recover equipment investment.

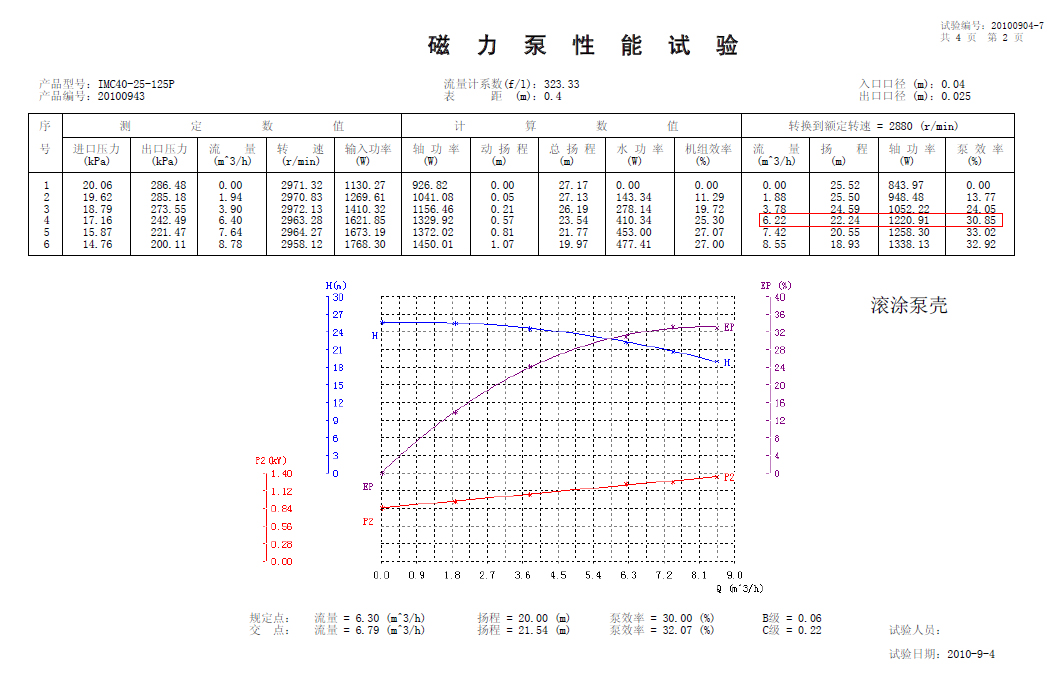

Comparison of energy consumption of IMC40-25-125P plastic magnetic pump (pump shell roller coating and lining)

|

|---|

1. Shaft power: the actual power consumed by the pump;

2, serial number 1 is a plastic magnetic pump using the rotoplastic process and the use of advanced hydraulic model, serial number 2 is a plastic magnetic pump using the plastic lining process and the use of general hydraulic model;

3. Shaft power is the power consumed by the pump in real time;

4, serial number 1 and serial number 2 is the same plastic magnetic pump, serial number 1 than serial number 2, calculated in accordance with 360 days a year, the electricity consumption is less than 3543 yuan (14083 yuan – 10540 yuan), if the model is larger, the energy gap is also larger.

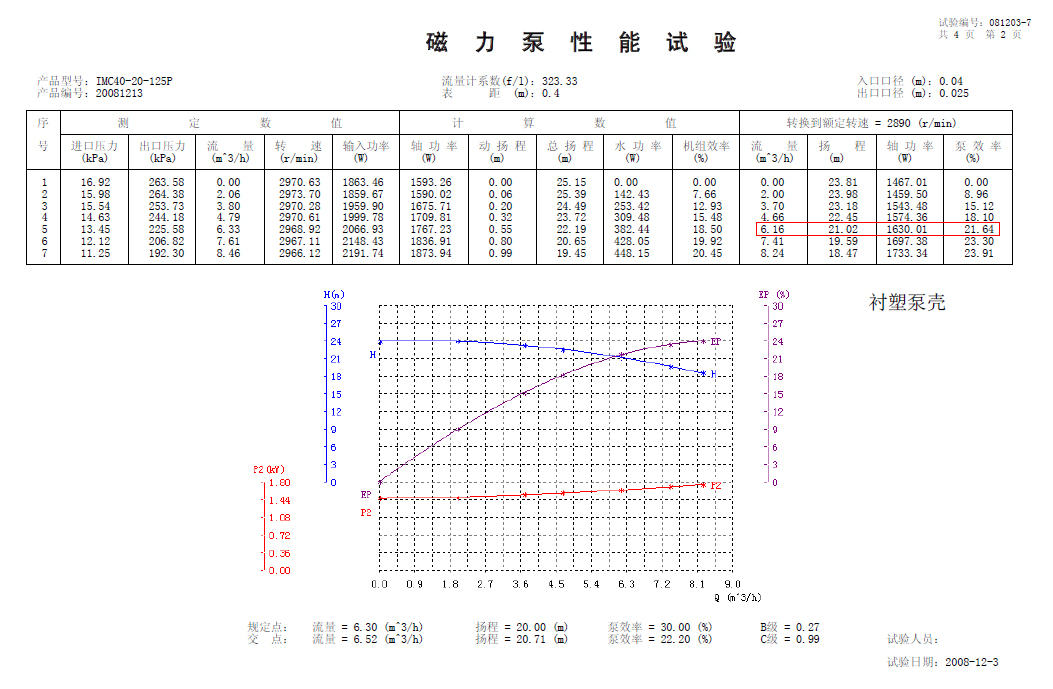

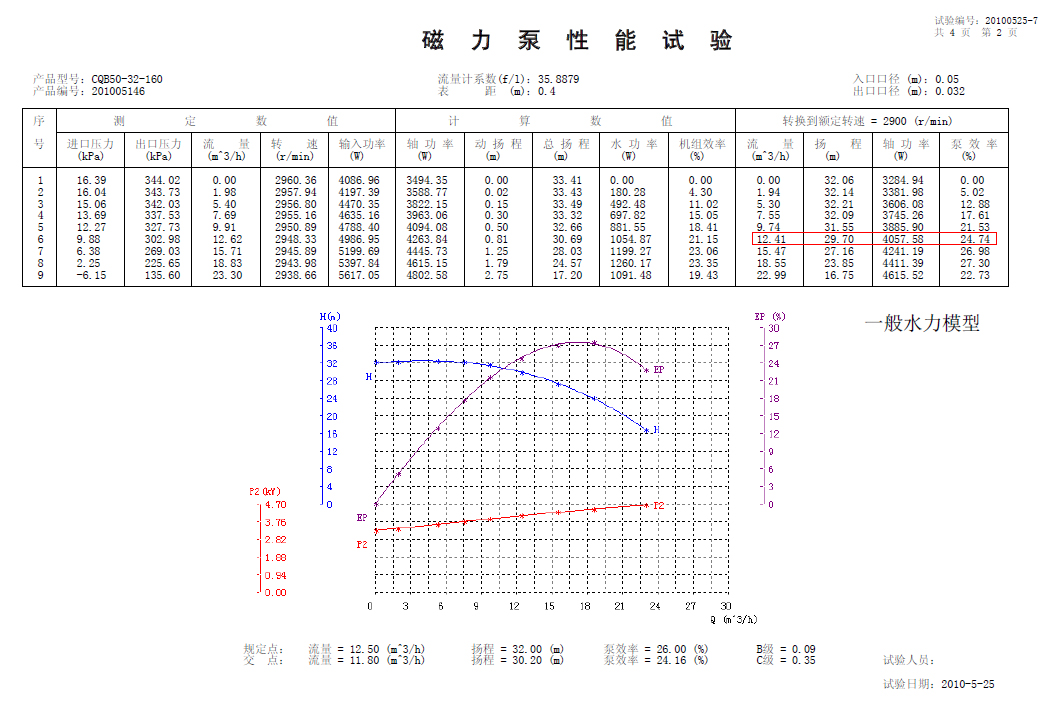

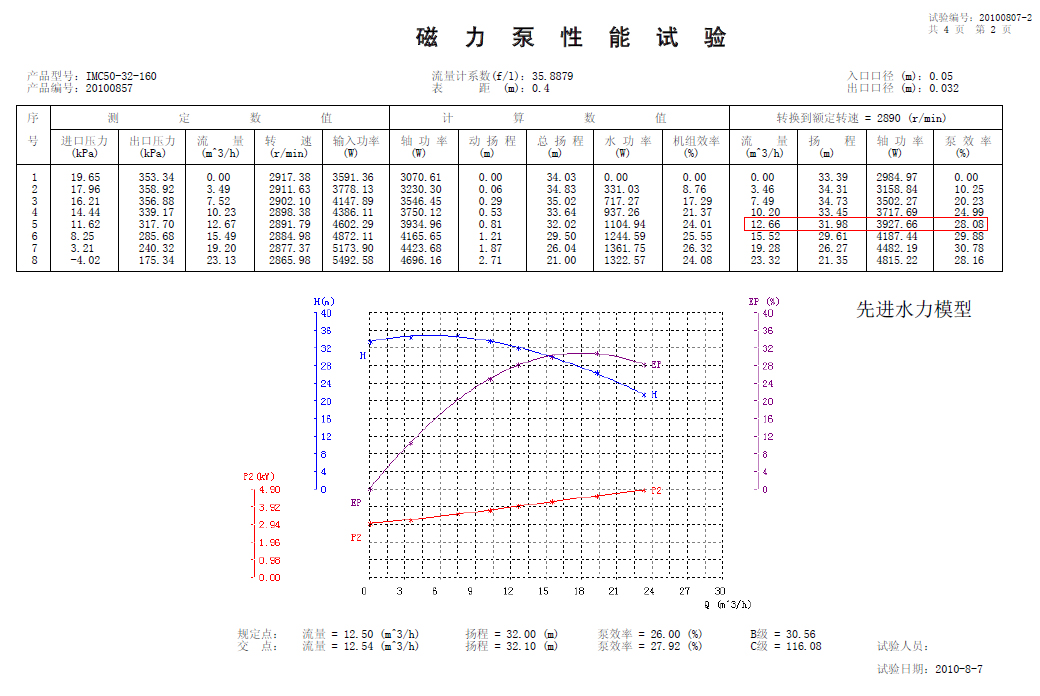

IMC50-32-160 Metal Magnetic Pump (Advanced Hydraulic Model And General) Energy Consumption Comparison

|

|---|

1. Shaft power: the actual power consumed by the pump;

2, serial number 1 is an advanced hydraulic model of magnetic pump, serial number 2 is a general hydraulic model of magnetic pump;

3. Shaft power is the power consumed by this pump in real time;

4, serial number 1 and serial number 2 are also metal magnetic pump, serial number 1 than serial number 2, calculated in accordance with 360 days a year, the electricity consumption is less than 1123 yuan (35057 yuan – 33934 yuan), if the model is larger, the energy gap is also larger.

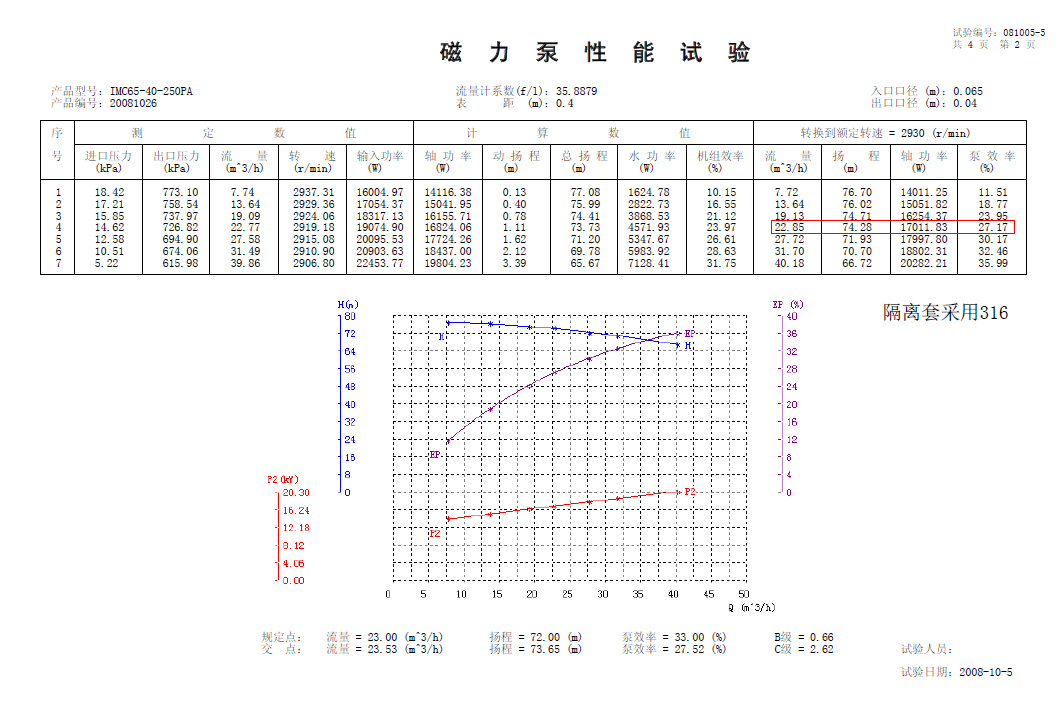

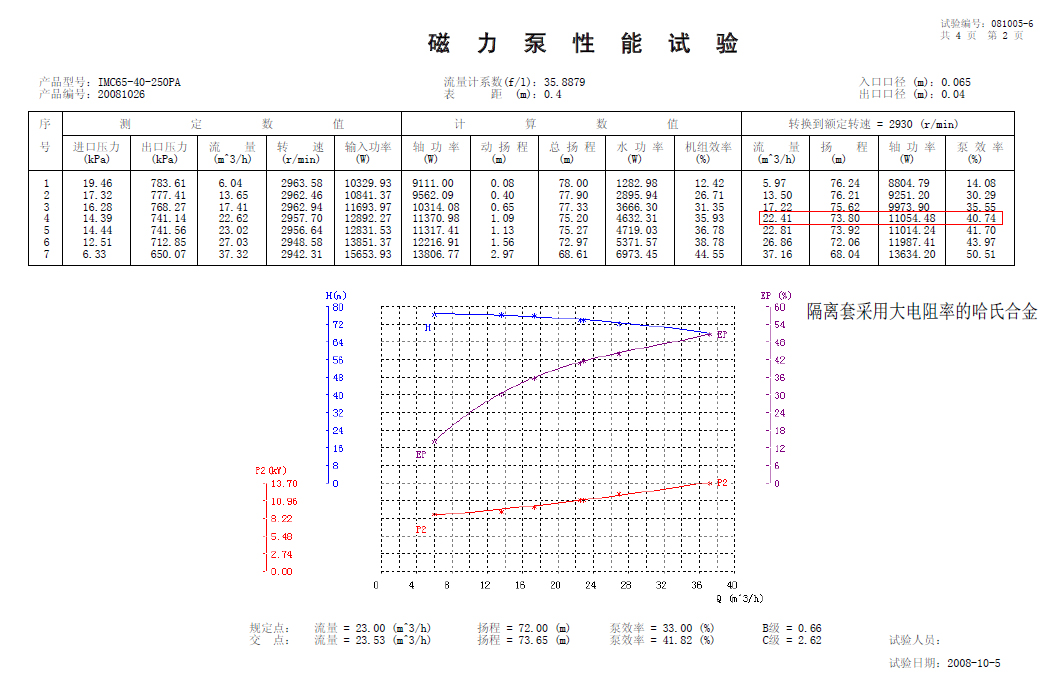

Comparison of energy consumption of IMC65-40-250A metal magnetic pump (Hastelloy sleeve and stainless steel sleeve)

|

|---|

1. Shaft power: the actual power consumed by the pump;

2. Serial number 1 is a magnetic pump with an isolation set made of Hastelloy material and an advanced hydraulic model; Serial number 2 is a metal magnetic pump with a stainless steel material and a general hydraulic model;

3. Shaft power is the power consumed by this pump in real time;

4, serial number 1 and serial number 2 are also metal magnetic pump, serial number 1 than serial number 2, calculated in accordance with 360 days a year, the electricity consumption is 51819 yuan (146,982 yuan – 95163 yuan), if the model is larger, the energy gap is also larger.

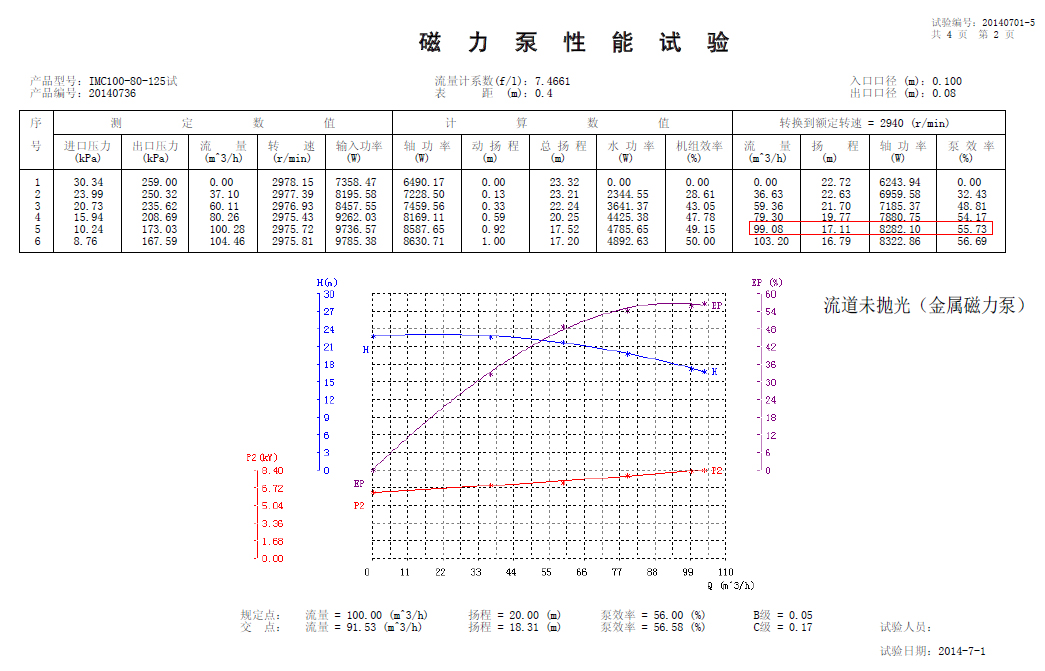

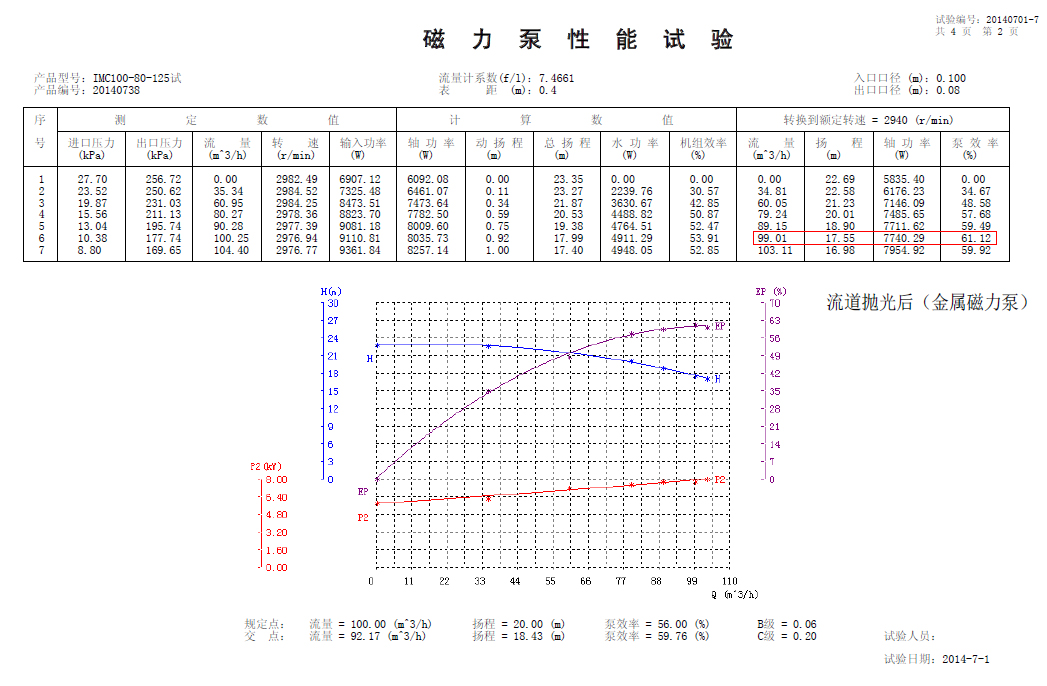

Comparison Of Energy Consumption Of Imc100-80-125 Metal Magnetic Pump (Impeller Channel Treated And Untreated)

|

|---|

1. Shaft power: the actual power consumed by the pump;

2. No. 1 is a magnetic pump with polishing technology for impeller runner, No. 2 is a magnetic pump without polishing technology for impeller runner Magnetic pump with polishing technology;

3. Shaft power is the power consumed by this pump in real time;

4, serial number 1 and serial number 2 are also metal magnetic pump, serial number 1 than serial number 2, calculated in accordance with 360 days per year, the electricity consumption is less 4681 yuan (71557 yuan – 66876 yuan), if the model is larger, the energy gap is also larger.